How we have reduced the number of complaints – a solution for a customer from the automotive industry

How to protect a product against scratches during assembly on a production line

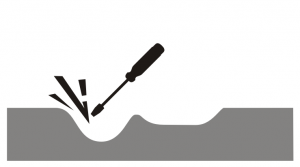

One of our customers – a manufacturer of car interior equipment components – has been struggling with the problem of scratches and damages on the produced parts for a long time. The product is a high-gloss control panel for lighting and sunroof. During the assembly of individual components there is a probability of scratching the external surface of the panel. The requirements concerning the quality of workmanship are very strict. Even the slightest scratch causes the panel to be rejected by the customer’s quality department.

These problems arose for our customer during the assembly of larger components. As the attention to detail affects the quality of the final product, it was a big problem for the customer. It represents the demanding automotive industry.

In the production process, each subsequent element is mounted on special ” “benches ” made of plastic. The panel is also made of plastic. This detail needs to be protected against scratches. Until now, the customer has been provided with a glueless material from another supplier, which is covered with double-sided tape by employees. An employee glued 10 pieces of double-sided tape of different lengths to each element. One production line has 30 workplaces, the detail is produced on two lines. Undoubtedly, it causes additional costs and extends the time of production. In addition, the problem is the material itself, which, when wiped off, shreds, dusts and dirts the detail itself.

Foam and transparent polyurethane turned out to be undurable

After consulting the R&D department, we offered the client an alternative material – initially EPDM foam and transparent polyurethane. However, it turned out that they did not meet the customer’s requirements. The foam was being damaged in the corners after placing the detail several times. In the end, this solution proved to be short-lived. On the other hand, after using polyurethane, the friction was too high and the customer had a problem with pulling the detail out of the “bench”.

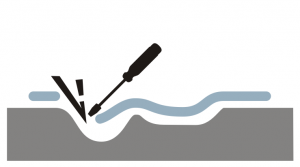

Agrotextiles with double-sided adhesive tape – no scratches, saving time

Benefits for the customer

It turned out that this solution fully eliminated the customer’s problems:

- saving time (currently the employees do not have to tape the material themselves, because they have a ready-made backing already delivered),

- providing a higher quality product,

- most importantly, without scratching the surface.

To sum up, if you have a problem with the proper protection of a product during the production process, please contact our experts.

(77)