Barcode verification – Etisoft solution for the Regional Centre for Blood Donation and Blood Treatment

How to efficiently eliminate illegible barcodes

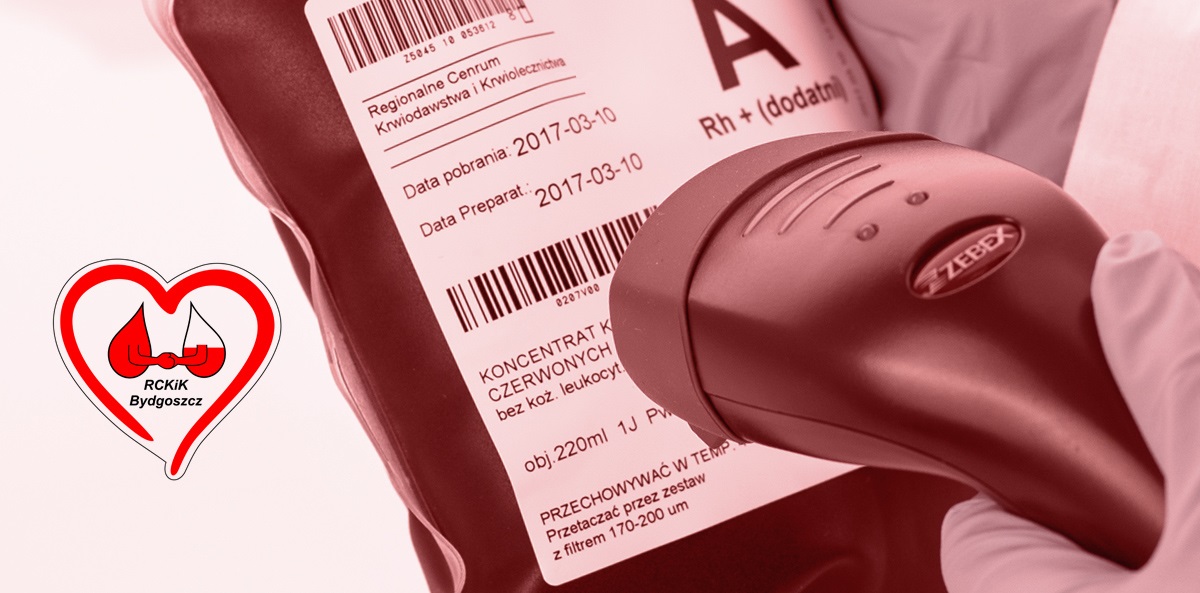

The Regional Centre for Blood Donation and Blood Treatment in Bydgoszcz uses barcodes for marking and circulation of test tubes and drainage tubes, and for marking all containers for blood. These are individual codes for each donation, unique on an international scale and compliant with the ISBT 128 standard. The donation codes need to be unique and legible for the system to function properly. The existing solution applied at the Regional Centre for Blood Donation and Blood Treatment did not ensure a sufficient level of code verification.

Drawing, processing, testing, storing and distributing blood and its components are subject to many strict regulations. There is huge responsibility that blood centers need to face which is not only related to the quality of tests. Attention is also paid at every stage of management of testing material so that no mistake or error is made. The health and life of patients may depend on that.

How to reconcile printing quality, elimination of illegible codes and supervision over numbering

Etisoft, that had already come up with many solutions for pharmaceutics and laboratories, had to find a solution that:

- ensures appropriate printing quality

- eliminates illegible codes

- will supervise the numbering for each department

- will automatically print out a report after a batch of labels that includes:

- operator’s name tag

- start of donation printing

- last donation number

- printing date and time

- number of donations

- number of incorrect printouts

- other data required by the ordering party

- will automatically print bulk label for the container with printed codes with information regarding the scope of numbers

The new system is supposed to cooperate with the existing way of printing labels and exchange data regarding the numbers with it in order to ensure proper printouts in both systems at any time.

Immediately checked correctness of barcodes

We proposed our authorial etiLABEL Professional software to the Client. We chose PRINTRONIX PTX T8000 printer with barcode validator to work with the software. Validation consists in objective and immediate check of the barcode correctness with regard to its legibility. It is checked after printing of each batch which, in this case, consists of 20 labels in a pad. The labels that do not comply with the norms are marked as incorrect and destroyed by means of their complete overprint. The operator receives a validation protocol after each completed cycle. It is worth emphasizing that there is an option that makes it possible to individually set the elements which we want to be verified.

After the tests, the whole solution proved to be an optimum solution that ensures the fulfilment of all tasks set and thus the Centre gained a tool that guarantees safety of tests across the entire chain.

(123)