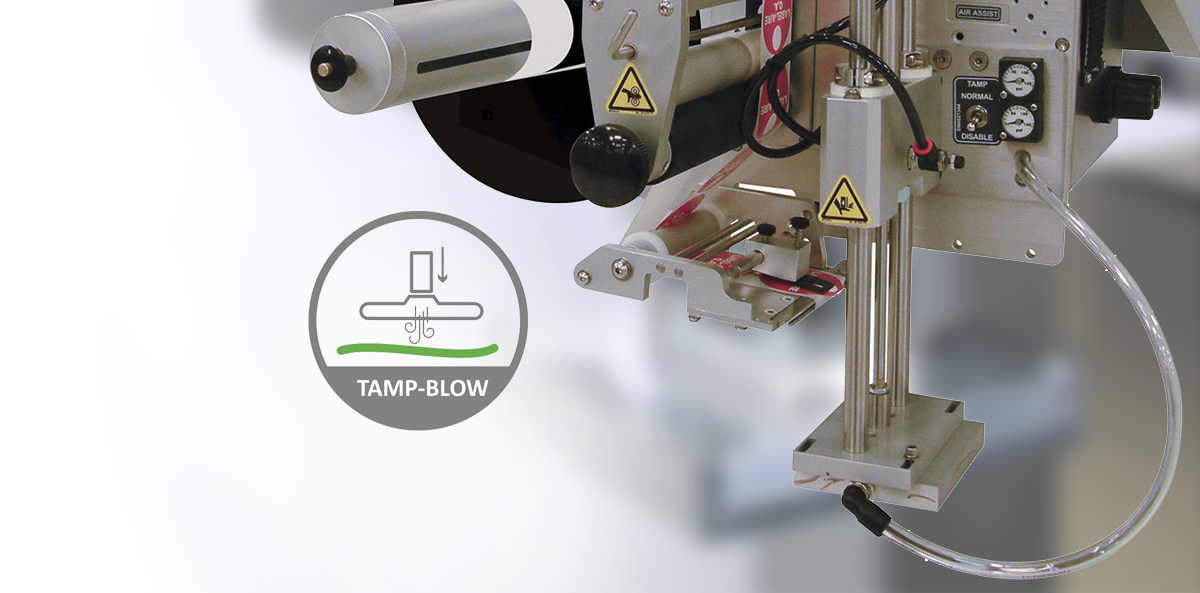

Tamp-Blow label application method

Universal label and tag application

The Tamp-Blow application method is the most universal method of applying labels or tags on products. The primary difference on relation to the Wipe-On / Merge method (link) is the extra use of compressed air involved directly during the label application process. The Tamp-Blow label application method requires more additional steps in order to set correctly all parameters of the applicator to achieve satisfactory accuracy and efficiency of application.

This universal Tamp-Blow label application can be divided into four main stages:

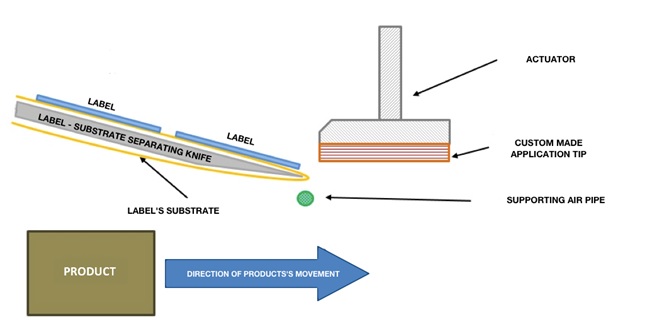

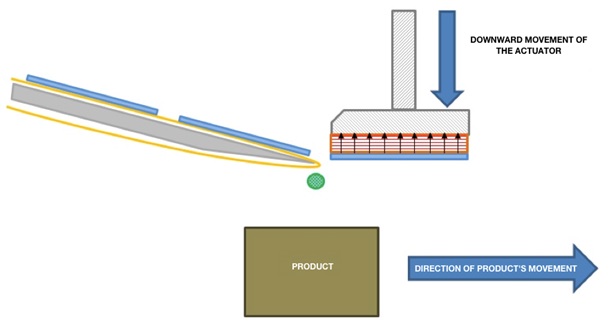

The “stage – one” of the Tamp-Blow label application

State before starting the application. The first label is on the substrate at the peeling edge. The product moves on the conveyor.

Stage two – Label’s separation from the substrate

Rolling of the label’s substrate follows. The label at the edge of the knife is being separated from the substrate. Negative pressure is generated on the applicator’s tip to lift the label. At the same time the supporting blow of air occurs from the tube holes just below the edge of the knife. The number of holes depends on the width of the label and its thickness/stiffness. In most applications one hole is sufficient. The purpose of the supporting air is to raise the edge of the label after it has been separated from the substrate in order to reach the edge of the applicator tip with the negative pressure. The duration of the supporting airflow is usually equal with time needed to separate the label from the substrate.

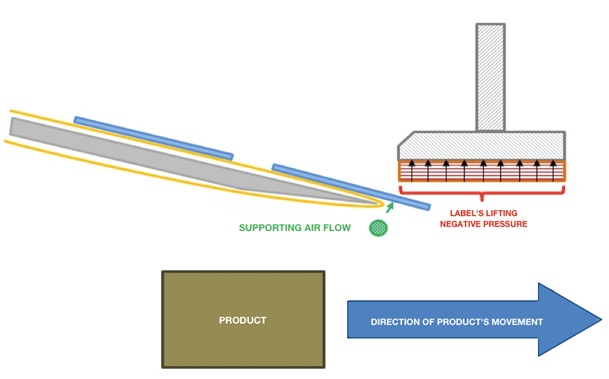

Stage three – the label held by the negative pressure

The entire label has been separated from the substrate and is being held by the negative pressure at the applicator’s tip. Detection of the product’s sensor on the conveyor triggers the actuator downward. The label is still being held by the negative pressure.

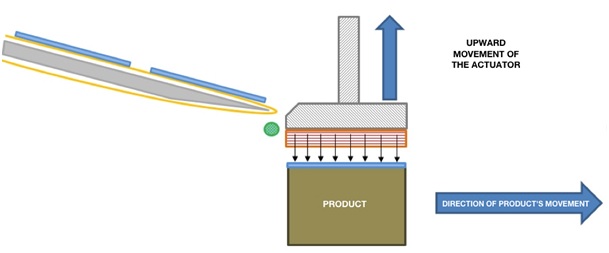

The last stage – label’s airflow on the product

When a sufficient leap has been reached by the actuator to allow the label to reach the surface of the product at a distance allowing the proper application (2-3 mm recommended), the negative pressure is being turned off and a rapid blow of the label on the product follows. The actuator returns to the starting position and the entire application process starts again from stage one.

Main characteristics of the Tamp-Blow label application

- contactless method – label is inflated directly onto the marked surface without any contact of the applicator with the product,

- no speed synchronization required – the product can move at any speed, which does not have any affect on the speed of label’s separation from the substrate,

- direction of product’s movement is irrelevant – transporter, on which the marked products are located, can move in any direction. Since there is no direct application of the label after it’s separation from the substrate, the applicator’s orientation (left/right) does not matter,

- high speed of application – thanks to the strengthened motor (rolling speed up to 127 m/min) and fast actuators, the performed efficiency is very high,

- separate pad for each label size – for the highest precision of the label’s application, the same size of the applicators tip (as the size of the label itself) is recommended,

- perfect for small label’s application – thanks to the negative pressure and an air flow we are sure that the label was lifted from the substrate and applied without even a slight rotation or a slip on the surface of the product,

- application on the limited space – usage of actuators of different leap lengths allows the label to be applied in hard-to-reach places on the production line and e.g. in product’s recesses.

Proven application method in logistics, weighing systems and individual marking systems

The Tamp-Blow label application can be successfully used for moving and non-moving products. In the second case, if the specificity of the product permits or it is required, by means of the applicator’s tip we can touch the product’s surface applying pressure in order to firmly attach the label. For this purpose, special resilient tips are used or they are covered with an additional soft material.

Applicators using the Tamp-Blow method, thanks to its universality, are used in all production processes. Such applicators are greatly configurable and can cooperate with printing modules, which allow “1 to 1” printing and applying method (the printed label is exactly the one that should be found on the product), is ideal for weighing systems, logistics and wherever individual product’s markings are used (e.g. serial numbers, batch numbers, numbering, date/time).

(1497)