Advanced IT tools are helpful when time matters

etiSZOP identifies and supports production processes

Proper production process organization requires coordination of numerous activities. One of the main roles here is played by internal logistics, which is considered by modern organizations as a key management tool. Etisoft Internal Logistics department is strongly supported by advanced IT solutions. It is worth mentioning that tools we use internally are also offered and used by our customers.

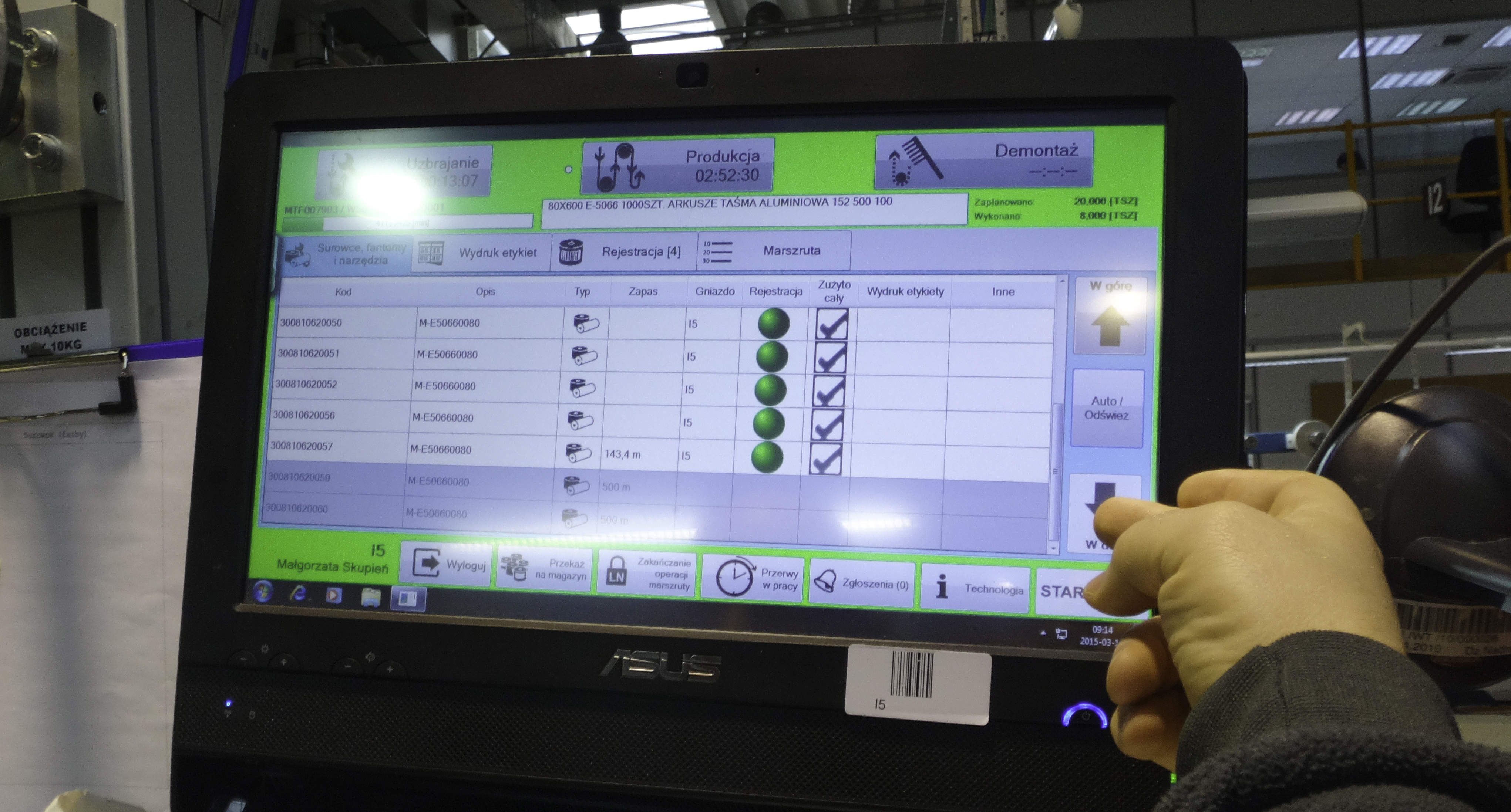

So called etiSZOP (Production Batch Flow Management System) is our own project which supports internal logistics process since 2014, when ERP system was implemented and reflects our activity towards implementation of lean management. In simplest words – etiSZOP identifies and supports production processes and problems that may occur in every production phase. It works in a real-time. It operates with full traceability of each component and one of its supportive tools are synoptic tables.

Instant access to information

Mobile solutions visible from every corner of production floor informs that an intermediate needs to be collected from the machine in order to be transported to the warehouse or other manufacturing cell. Once the production operator reports completion of a given task, it is being automatically identified by the system which also recognizes further operations.

Synoptic tables also help shift managers to verify production stage and its lead time. Also, provides information on potential equipment failures, rearms or stoppages caused by other factors. If an intermediate requires quality control, such information goes directly to quality department employees and it is all thanks to synoptic tables.

Information passed by synoptic tables are completed by call-over tables. This is a dedicated solution for internal logistics, technology, maintenance and quality departments. The system encodes information about every element necessary for production of any part. By using the tables, production operator, without interfering production process, may pass information about lacking raw material, consumable, etc. The system visually informs also about raw material damage or faults. Additionally, the information about this last item is also passed to shift managers’ mobile phones. It allows maintenance department to take actions immediately and reaction time is optimally shortened due to a detailed, automatic occurrence identification. “The red lamp” for quality and technology department appears also during first production of a given product which allows full and thorough process control.

When reaction time matters

Tool tables based on etiSZOP were designed in such a way to inform in advance which tools are needed to produce a given product. Tools for three orders in advance are shown on the table, while every time the table shows need for a tool with a certain resumption number. Each tool fault is registered in the system, as well as any other reasons for tool unavailability. What it means for a production operator is that tool table always shows proper and adequate information, which allows faster machine rearm. The system also prevents usage of a broken tool, which eliminates human mistakes. Similarly to tool tables also print support tables operate. Production operator knows in advance about necessary tools, production phases or faults.

Examples: the system informs about damaged raw material for label production. Thanks to etiSZOP we may state with 100% certainty which tool caused the damage. This enables fast reaction: detection of potential fault, its diagnosis and withdrawing tool and raw material from workflow. Other potential benefit from implementation of etiSZOP: full control on raw material supply. If our supplier changed marking, for example, internal logistics employees are able to verify that at the very early stage of raw material admission and quickly undertake accurate actions.

etiSZOP benefits:

- Facilitation of internal logistic process,

- Full control over production process,

- Elimination of production stops and breaks, maintaining production continuity,

- Scheduled order completion, elimination of delays,

- Eliminating risk of making a mistake,

- Raw material management according to FIFO.

Full tool and software traceability allows to eliminate any kind of abnormalities, predict them and prevent. This interesting solution allowed to coordinate actions of various departments and internal logistics management in a more efficient way which consequently influenced production process. If we compare number of breakdowns in Etisoft before and after implementation of etiSZOP, we clearly see the system works and is an important tool allowing us to fulfill demands of our clients.

(65)