Switchboard Panel Labels – “foam labels”

Label printing system. SPL Labels

Imagine any device without description on function keys, server room or chemical installation without any description or – more prosaically – the doors in offices without number or name of the department.

What does it mean? Disinformation, or even a dangerous situation. Fortunately, the industry regulations

in the field of security and order of certification bodies require manufacturers and administrators to sign their products in appropriate way. According to the regulations, the sign should be visible, clear, durable, and if it is in the form of written in language understandable to the user.

Enterprises engaged in the production on individual demand, and such are the manufacturers of control equipment, switching stations, or installation, where each product is different, often face a problem where to order right descriptions. We are not talking about labels: “Caution”, “Start” or “Stop” because these as typical are easly available. We are talking about unusual and unique markings, such as “Wind Power Plant Control Room 1”.

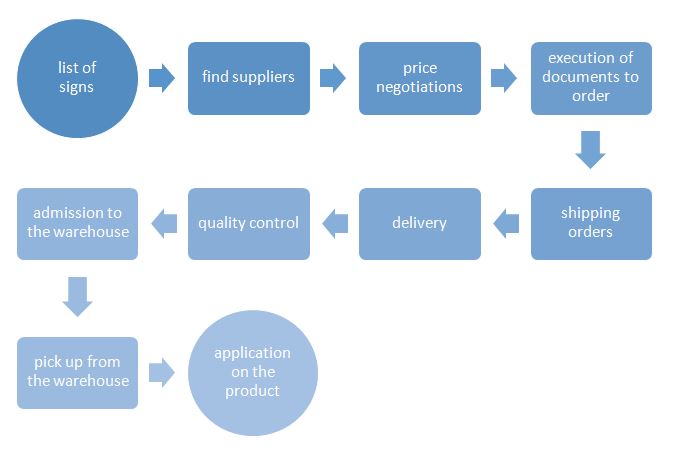

Commonly used markings in the form of metal or plastic plates, engraved using a laser technology of course comply with the relevant regulations and standards, but the processof obtaining them is long and costly. Typically, when estimating the cost of the signs we take into account only the cost of the same “tablets”, bypassing the operating costs associated withits acquisition.

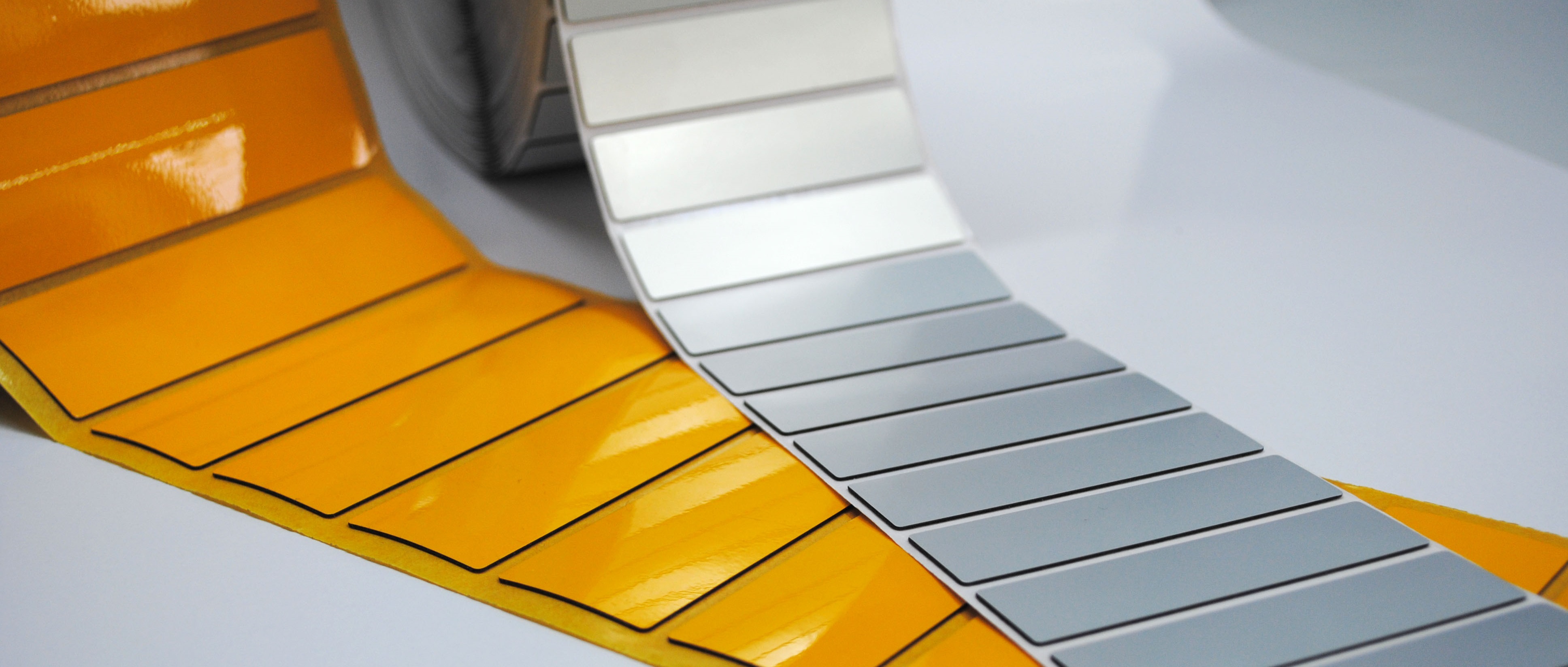

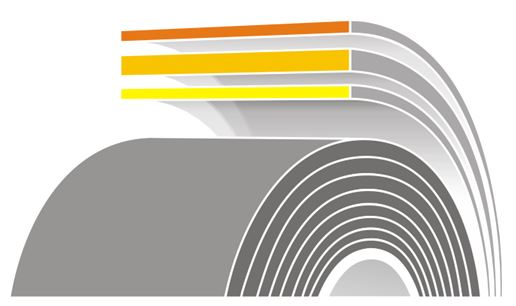

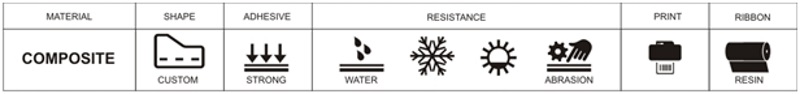

Considering the above aspects, Etisoft introduced the marking system based on self-adhesive labels printed by thermal transfer printers. This is a label made of high quality thick polyester backed with polyethylene self-adhesive foam.

Layered structure:

Technical parameters:

- a thickness of about 0.8 mm.,

- acrylic adhesive,

- service temperature range from -40OC to +80 OC (130 OC for short periods),

- good resistance to UV,

- high resistance to water and some chemicals.

Colours:

Proposed in this system SwitchBoard Pack labels are printed on thermal transfer printers, which means that we restrict to a minimum the operating costs of their execution.

Citizen Consumables Program

Of course, before we have to purchase suitable formats of labels and ribbon. In this case, the entire operational costs come down to select and order the appropriate format from the list of SwichBoard Pack products which are a part of Citizen Consumables Program.

It is worth to know that Switchboard Pack label is 2 to 3 times less expensive that similar engraved plaque!

Costs of implementation:

It would be unfair to skip the costs of imple-menting a printing system, but as shown below, they are not too high and comparing the prices of the same signs implementation costs quickly pay for itself.

- recommended Citizen CL-S730 costs – 1360 €

- designing software etiLABEL – starts from 49 €

It should be noted that the offered device can be used in the enterprise also to print other labels, such as nameplate, marking cables, sockets, etc. designation.

These consumables are also available in the Citizen Consumables Program.

Applications:

- marking cabinets,

- marking machines,

- marking of pipes and installation,

- safety signs,

- signs in the administration.

Advantages:

The thickness of the label significantly affects the aesthetic indications by which SwitchBoard Pack labels are an excellent alternative to engraved plates. The adhesive layer ensures high-quality connection even with materials of low surface energy, such as. Powder coated metal casing. Use in construction of polyethylene foam makes the label perfectly adaptive to uneven surface, which increases to virtually 100% contact surface of the label to the substrate to form a stable connection. This thick polyester label will always be perfectly flat regardless of surface iregu-larities on which the label will be fixed. Printing on thermal transfer printers directly at the production site means that you can quickly get the appropriate quality mark.

Benefits:

Unlimited applications, aesthetics and price make SwitchBoard Pack labels attractive for many manufacturers from various industries and can successfully compete with commonly used engraved markings.

- low cost of implementation

- of the printing system,

- reduction of operating costs,

- by engaging a limited amount of resources,

- low price of markings,

- short time of production,

- option of printing directly from database.

(303)