Automatic stand for Print&Apply devices

Automatic stand for Print&Apply devices – advantages of implementation

Automatic marking of products with labels often requires changing the location of the labels during the production process. As a standard, this changeover is carried out manually. The operator who wants to change the settings is forced to make them during (usually a short but necessary) technical break causing production downtime.

Manual positioning of the applicator, both in terms of the height of the mounting (changing the height of the product to be marked or the location of the label) and its position in relation to the width of the transport line, can also be successfully done with the use of an automatically adjustable stand.

Automatic stand in the Print&Apply process

An example of such a solution is the implementation made by Etisoft at one of the customers, who decided to introduce an automated process of marking of wrapped pallets with products. The problem with the application was that they had to be made using two labels placed on the adjacent sides of the pallet, while taking into account the changes in its height. Until now, the labels were applied manually, after printing them on a stationary thermal transfer printer.

The solution

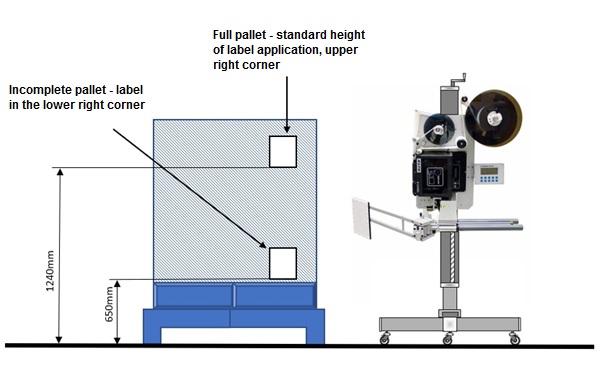

We assumed that pallets on the conveyor are to be automatically marked with two labels: one in the upper right corner (front of the pallet) and the other – in the upper left corner (side of the pallet). It turned out quite quickly that the process of their application contains some difficulty. The nature of production made that some pallets, most often being the ends of a given production batch, are not filled to the top.

As a result, it was necessary to change the mounting height of the printing and applying device. At the same time, according to the customer’s requirements, the process had to be fully automated. That is why continuous human supervision and changes in the position of the applicator by operators on the line were not acceptable.

Innovation

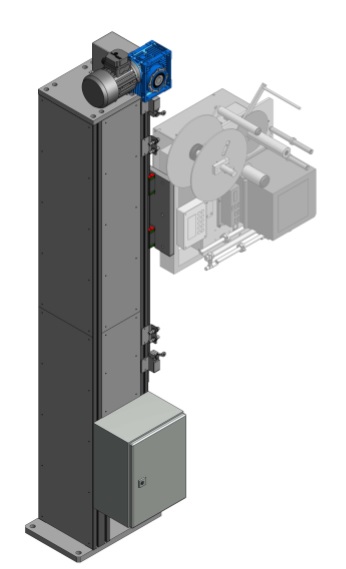

For the purpose of implementation we have designed and built an automatic stand that meets the customer’s requirements. On the rack we placed the Label-Aire 3138NV-DAT application device with an arm that allows the application of two labels on the adjacent sides of the product. In the system, we also used the Zebra ZE500-6 printing module.

This construction, in the form of a column, is a free-standing device fixed to the ground with 4 screws.

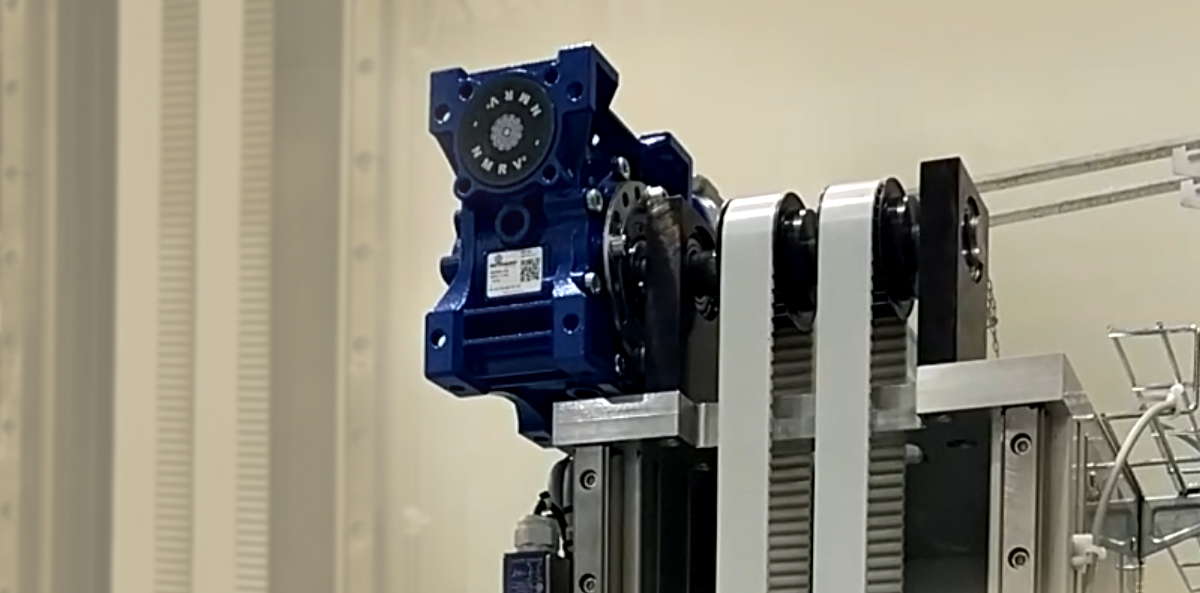

The inverter we used controls an electric motor with a gearbox. We have also added inductive sensors, which determine the maximum upper and lower position of the applicator setting.

In the construction we also used safety limit switches. The whole is made of aluminum and stainless steel. Suspended applicator moves on the plate with linear carriages moved by toothed belts.

Parameters of the device

Travel speed approx. 150 mm/sec.

Maximum load capacity of the rack – 120 kg.

The appreciated control solution is also noteworthy. The superior control system on the customer’s side decides whether to hang the applicator at the maximum height (full pallet) or minimum height (incomplete pallet). The system makes a decision based on the results of detecting the level of pallet filling by optical sensors. In addition, we have added the possibility to smoothly move the applicator to intermediate positions. They are used for service activities or e.g. when replacing consumables.

Automatic stand for Print&Apply – additional options

In the advanced version of the stand we have added the possibility of using encoders or programmable stepper motors. This option allows you to use any position of the applicator for different heights/widths of the product. This allows you to handle the entire range of manufactured products or final packaging without interrupting the process. Practically any type of label applicator or printing and applying device can be mounted on the stand.

Benefits of the solution

The results achieved through innovation significantly improve the production process at the customer’s site. Based on this implementation, it is worth mentioning the most important benefits of the automatic Print&Apply rack:

- a solution dedicated to each customer

- the use of any application and printing modules

- fully automatic height-adjustable

- the use of a system for applying labels in short production batches

- repeatability and accuracy in the Print&Apply process

- time saving – no technical interruptions to set up the device

Summary

The automatically adjustable stand is the ideal solution for short series marking. It provides repeatable marking accuracy with variable product dimensions. It saves valuable time previously wasted on rearming the production line.

If you would like to know more about the automatic device rack, please contact us.

(166)